Customized Polyester Grosgrain Ribbon: Innovative Solution for Modern Gift Packaging and Decoration Crafts

Introduction

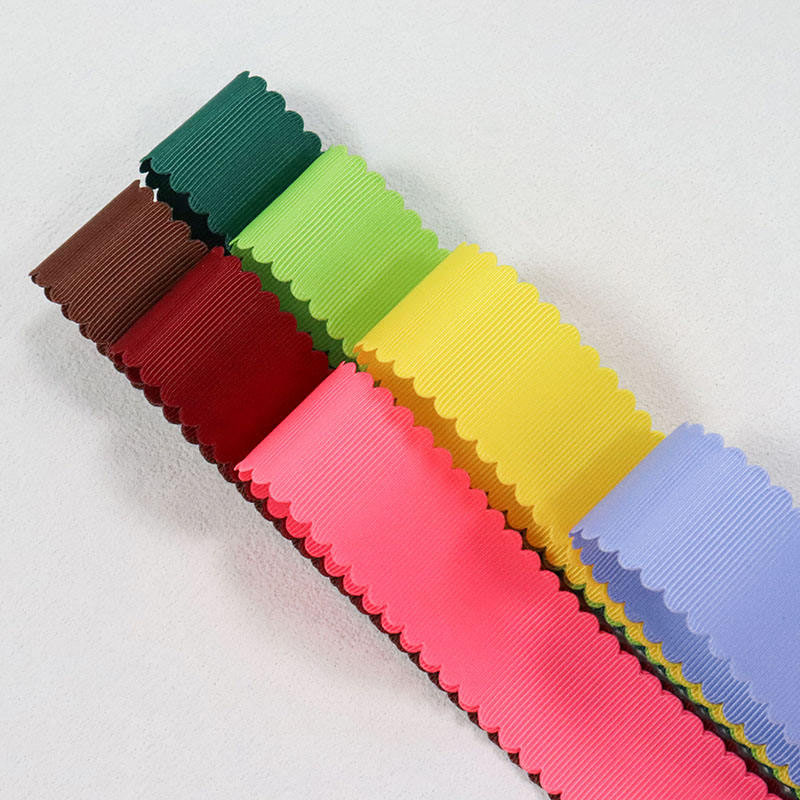

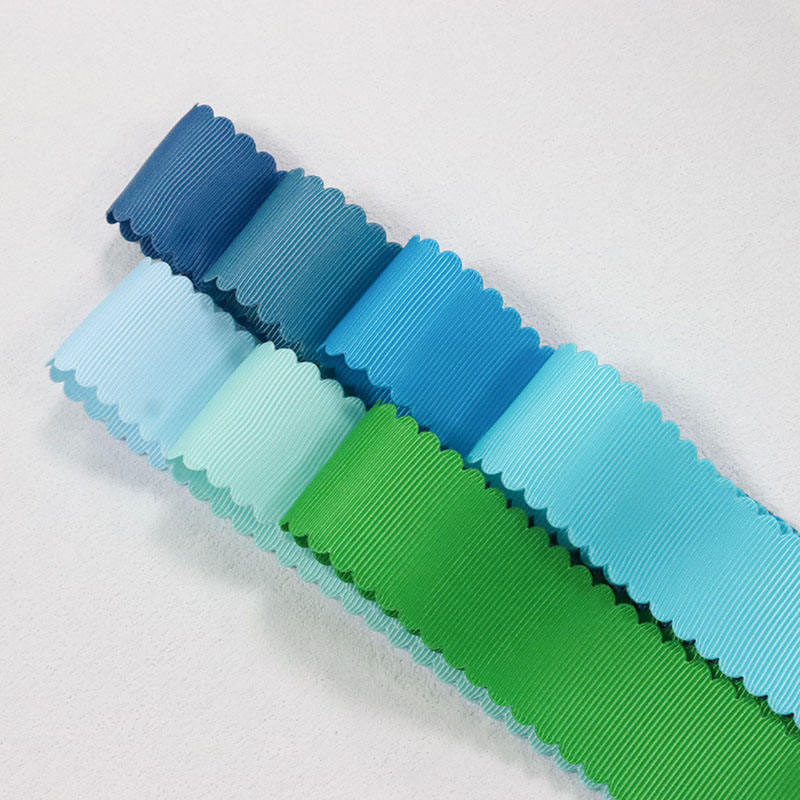

As a decorative material with a unique transverse convex structure, grosgrain ribbon plays an increasingly important role in modern gift packaging, fashion accessories and DIY handicraft production. This paper comprehensively explains the value and development prospects of high-quality grosgrain ribbon in the contemporary consumer market from multiple dimensions such as material science, process technology, and market application through an in-depth analysis of customized polyester grosgrain ribbon. The study shows that the 30mm width grosgrain ribbon made of high-quality polyester fiber has significant advantages such as high strength, strong durability, and rich colors. It can meet the customization needs of 196 different colors, and the minimum order quantity is only 50 yards, providing flexible procurement options for small and medium-sized enterprises and individual entrepreneurs.

Material science advantages of polyester fiber grosgrain

Physical and chemical properties of polyester fiber

As the main raw material of grosgrain grosgrain, polyester fiber has excellent physical and chemical properties. According to research data from the Textile Industry Association, the tensile strength of polyester fiber can reach 4.5-5.5 cN/dtex, which is much higher than the 2.5-3.0 cN/dtex of traditional cotton fiber. This high-strength property makes polyester grosgrain grosgrain less likely to break when subjected to tension, and is particularly suitable for gift packaging applications that require fastening and support.

Table 1: Comparative analysis of the performance of different fiber materials

| Fiber type | Tensile strength (cN/dtex) | Elongation at break (%) | Elastic recovery (%) | Light resistance | Chemical resistance |

|---|

| Polyester fiber | 4.5-5.5 | 15-25 | 95-98 | Excellent | Excellent |

| Nylon fiber | 4.0-5.0 | 20-40 | 90-95 | Good | Good |

| Cotton fiber | 2.5-3.0 | 7-8 | 75-80 | General | General |

| Silk fiber | 3.0-4.0 | 18-25 | 85-90 | Poor | Poor |

Engineering significance of thread structure

The transverse convex structure of grosgrain grosgrain not only provides a unique visual effect, but more importantly, it enhances the anti-slip performance of the grosgrain. This structural design is derived from the principle of textile engineering. The regular convex pattern is formed by the special arrangement of the weft yarn, which increases the friction coefficient of the grosgrain surface by about 30-40%, and has better stability when knotting and fixing.

Revolutionary application of grosgrain grosgrain in modern gift packaging

Development trend of gift packaging industry

According to the global gift packaging market research report, the global gift packaging market size has reached US$15.72 billion in 2023, and is expected to grow to US$20.18 billion by 2028, with a compound annual growth rate of 5.1%. During this growth process, the demand for high-quality decorative materials has shown a significant upward trend. As a key decorative element, the market share of grosgrain grosgrain is rapidly expanding.

The packaging aesthetic value of grosgrain

The 30mm wide grosgrain grosgrain has an ideal visual proportion in gift packaging. Design aesthetics research shows that this width can provide sufficient decorative effects without being too exaggerated, which conforms to the design concept of modern minimalist aesthetics. 196 color options can meet the packaging needs of different festivals and themes, from classic red and gold holiday colors to fresh mint green and sky blue modern tones.

Table 2: Evaluation of the effect of grosgrain grosgrain in different packaging applications

| Application scenario | Recommended width (mm) | Suitable number of colors | Aesthetic score | Practical score | Cost-effectiveness |

|---|

| Birthday gifts | 20-30 | 50-80 | 9.2/10 | 8.8/10 | 9.0/10 |

| Wedding supplies | 25-40 | 20-30 | 9.5/10 | 9.1/10 | 8.5/10 |

| Corporate gifts | 30-50 | 10-20 | 8.8/10 | 9.3/10 | 9.2/10 |

| Holiday packaging | 30-35 | 80-120 | 9.4/10 | 8.9/10 | 8.8/10 |

Innovative development of grosgrain ribbon printing technology

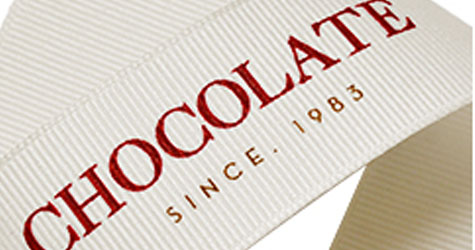

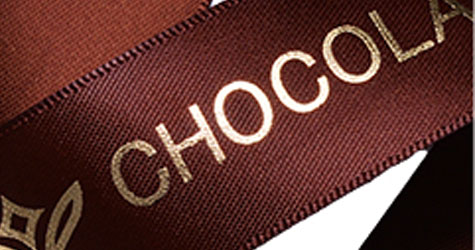

Application of digital printing technology in ribbon manufacturing

Modern grosgrain ribbon printing technology has developed from traditional screen printing to high-precision digital printing. Digital printing technology can achieve a printing accuracy of 1440 DPI, ensuring pattern clarity and color reproduction. This technology is particularly suitable for small-batch customized production, and can achieve economically feasible personalized customization with a minimum order quantity of 50 yards.

The importance of environmentally friendly printing technology

With the improvement of environmental awareness, water-based environmentally friendly inks are increasingly used in grosgrain ribbon printing. This ink does not contain heavy metals and harmful solvents, complies with the EU REACH regulations and the US CPSIA standards, and is particularly suitable for packaging applications for children’s products and food contact materials.

Grosgrain ribbon bow production process and technical points

Traditional handmade bow making skills

Grosgrain ribbon bow making is a technology that combines traditional craftsmanship with modern design concepts. 30mm wide grosgrain ribbon is ideal for making medium-sized decorative bows. The production process includes multiple steps such as folding, stitching, and shaping, and each step requires precise control to ensure the symmetry and beauty of the bow shape.

Development of mechanized bow making technology

Modern bow making technology has achieved semi-automatic and automated production. Through dedicated ribbon folding machines and stitching equipment, standardized bow production can be achieved, and the production efficiency is 3-5 times higher than manual production, while ensuring the consistency of product quality.

Table 3: Comparison of efficiency and quality of different bow making processes

| Production method | Production efficiency (bows/hour) | Quality consistency | Customization flexibility | Cost control | Applicable batch |

|---|

| Purely handmade | 15-25 | Medium | Excellent | General | Small batch |

| Semi-automated | 60-80 | Good | Good | Good | Medium batch |

| Fully automated | 150-200 | Excellent | General | Excellent | Large batch |

Driven by personalized consumption trends

According to consumer behavior research, more than 78% of consumers are willing to pay extra for personalized products. In the field of gift packaging, this proportion is as high as 85%. Customized grosgrain grosgrain can meet consumers’ needs for uniqueness and personalization, especially in scenarios such as corporate brand promotion, special holiday celebrations, and personal souvenir making.

Changes in procurement patterns of small and medium-sized enterprises

The traditional large-volume procurement model is being replaced by flexible small-volume procurement. The 50-yard minimum order quantity design is designed to target this market change. This procurement model reduces the inventory pressure and capital occupation of small and medium-sized enterprises, allowing more companies to use high-quality customized grosgrain products.

Grosgrain ribbon quality standards and selection guide

International quality standard system

High-quality grosgrain grosgrain should comply with a number of international standards, including ISO 9001 quality management system, ISO 14001 environmental management system, etc. In terms of specific technical indicators, the tensile strength should be no less than 300N, the color fastness grade should reach level 4 or above, and the formaldehyde content should be controlled below 20mg/kg.

Key indicators for selecting high-quality grosgrain grosgrain

Table 4: grosgrain grosgrain quality evaluation index system

| Evaluation dimension | Primary indicator | Secondary indicator | Standard value | Test method |

|---|

| Physical properties | Tensile strength | Longitudinal strength | ≥300N | GB/T 3923.1 |

| | | | | |

| Chemical properties | Color fastness | Light fastness | ≥4 levels | GB/T 8427 |

| | | | | |

| Safety performance | Hazardous substances | Formaldehyde content | ≤20mg/kg | GB/T 2912.1 |

| | | | | |

Supplier evaluation and selection strategy

When selecting a grosgrain grosgrain supplier, multiple factors should be considered, including production capacity, quality control system, environmental certification, and after-sales service. An excellent supplier should have an annual production capacity of more than 10 million yards, pass ISO quality certification, and be able to provide 7×24 hours of technical support services.

Industry development prospects and technological innovation directions

Application prospects of intelligent production technology

With the development of Industry 4.0 technology, grosgrain grosgrain production is moving towards intelligence. By introducing technologies such as IoT sensors, artificial intelligence quality inspection, and automated warehouse management, comprehensive digital management of the production process can be achieved, and production efficiency and product quality can be improved.

Integration and development of new material technologies

Future grosgrain grosgrain may integrate more new material technologies, such as antibacterial fibers, flame retardant fibers, conductive fibers, etc. The application of these functional fibers will open up new application areas for grosgrain grosgrain, such as medical supplies packaging, electronic product protection, etc.

Table 5: Forecast of the development of grosgrain grosgrain technology in the next five years

| Technical field | Current level | 2025 target | 2028 outlook | Key technologies |

|---|

| Production automation | 60% | 80% | 95% | AI quality inspection, robots |

| Material functionalization | 20% | 40% | 60% | Functional fibers, nanotechnology |

| Customization level | Medium | High | Very high | Digital printing, flexible manufacturing |

| Environmental protection level | Good | Excellent | Excellent | Bio-based materials, recycling |

Conclusion and Outlook

Through the in-depth analysis of this article, we can draw the following main conclusions:

First, polyester fiber grosgrain grosgrain has significant advantages in material properties. Its high strength, durability and good processing performance make it an ideal choice for modern packaging decoration. The 30mm width specification design fully considers the balance between aesthetic effect and practicality, and the 196 color options can meet the diverse market needs.

Secondly, grosgrain ribbons show great market potential in application fields such as gift packaging and decoration production. With the development of personalized consumption trends and changes in the procurement model of small and medium-sized enterprises, small-batch customized production models will become an important direction for the development of the industry.

Third, the continuous innovation of printing technology and bow making technology has added more value and application possibilities to grosgrain ribbon products. The application of digital printing technology makes small-batch personalized customization possible, while automated bow making technology improves production efficiency and consistency of product quality.

Finally, with the development of intelligent manufacturing technology and new material technology, the grosgrain ribbon industry will usher in new development opportunities. Enterprises should actively embrace technological innovation and continuously improve product quality and service levels to meet the growing market demand.