This comprehensive guide provides proven techniques for preventing ribbon fraying, ensuring your decorative elements maintain their professional appearance from production through final presentation. Whether you’re managing large-scale event decorations or overseeing retail gift-wrapping operations, these methods will help preserve the quality of your ribbon installations.

Understanding Ribbon Fraying: A Professional Perspective

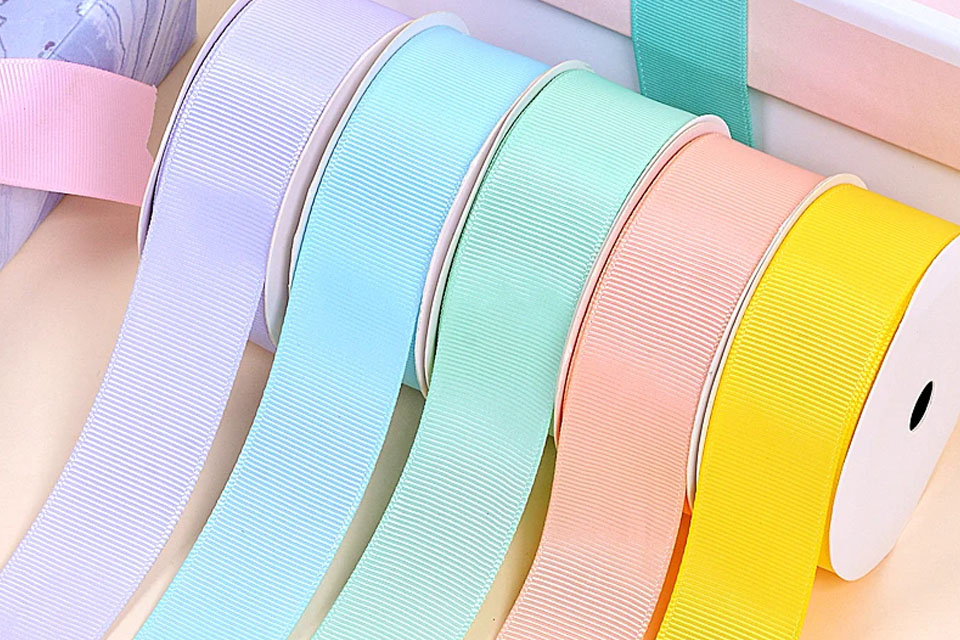

The integrity of ribbon ends directly impacts the perceived quality of your presentations. When working with ribbon, particularly in commercial applications, frayed edges can diminish the professional appearance of your finished work. This is especially important when using premium materials like grosgrain ribbons or delicate satin ribbons for high-end retail presentations.

Professional Heat Sealing Techniques for Commercial Applications

Heat sealing represents the industry standard for preventing fraying in synthetic ribbons. This method is particularly effective for volume production and professional installations:

Commercial Heat Sealing Equipment:

- Professional-grade wood burning tool

- Industrial ribbon cutting machine

- Controlled heat application systems

Industrial-grade ribbon processing equipment for professional applications

How Do Different Ribbon Materials Respond to Anti-Fraying Treatments?

Material-specific approaches are essential for optimal results:

- Velvet Ribbons:

- Requires gentle heat application

- Benefits from specialized edge sealants

- Temperature control is crucial

- Cotton Ribbons:

- Fabric-specific sealants recommended

- Natural fiber protection methods

- Chemical treatment considerations

Industrial-Scale Ribbon Processing Methods

For commercial operations handling large volumes, efficiency and consistency are paramount:

- Automated Systems:

- Heat seal along the edge

- Precision diagonal cuts

- Quality control measures

- Manual Processing:

- Professional-grade scissors

- Standardized cutting techniques

- Worker safety protocols

Professional Tools and Equipment Selection

Investing in proper equipment ensures consistent results:

Essential Commercial Tools:

- Industrial ribbon cutting machine

- Professional-grade sharp scissors

- Heat sealing equipment

Quality Control Measures for Ribbon Processing

Implementing systematic quality checks ensures consistent results:

- Edge Inspection Protocol

- Seal Testing Procedures

- Material-Specific Standards

Advanced Techniques for Special Materials

Different ribbon types require specialized handling:

- Special Occasion Ribbons:

- Custom heat settings

- Specialized edge treatments

- Premium finish requirements

- Organza Ribbons:

- Delicate heat application

- Special tool requirements

- Precise temperature control

Commercial-Scale Production Considerations

Volume processing requires attention to:

- Production Line Efficiency

- Quality Maintenance

- Worker Safety Protocols

Safety and Best Practices in Commercial Settings

Maintaining safe working conditions while preventing fraying:

- Proper Ventilation Requirements

- Heat Tool Safety Protocols

- Material Handling Guidelines

Expert Solutions for Common Challenges

Professional troubleshooting approaches:

- Temperature Control Issues

- Material-Specific Challenges

- Production Line Efficiency

Frequently Asked Questions

What is the most efficient method for processing large quantities of ribbon? For industrial applications, automated cutting and sealing machines provide the most consistent and efficient results while maintaining quality standards.

How can we maintain quality control in high-volume ribbon processing? Implement systematic quality checks, standardized procedures, and regular equipment calibration to ensure consistent results across production runs.

What safety measures are essential when heat sealing ribbons? Proper ventilation, appropriate safety equipment, and thorough staff training are crucial for safe operation of heat sealing equipment.

Which methods work best for delicate decorative ribbons? Specialized low-temperature heat sealing tools and gentle handling techniques are recommended for premium decorative materials.

Professional Guidelines Summary

- Choose appropriate methods based on ribbon material and volume requirements

- Invest in professional-grade equipment for consistent results

- Implement proper quality control measures

- Maintain safety standards and worker training

- Consider material-specific handling requirements

- Document standardized procedures for consistency

These professional approaches ensure high-quality results while maintaining efficiency in commercial ribbon processing operations. For more information about our professional-grade ribbons and materials, contact our technical support team.