Learn the latest trends and knowledge from the leading manufacturer in China about ribbon business.

Mastering the Art of (Ribbon Bows): From Satin Ribbons to DIY Twist Tie Bows

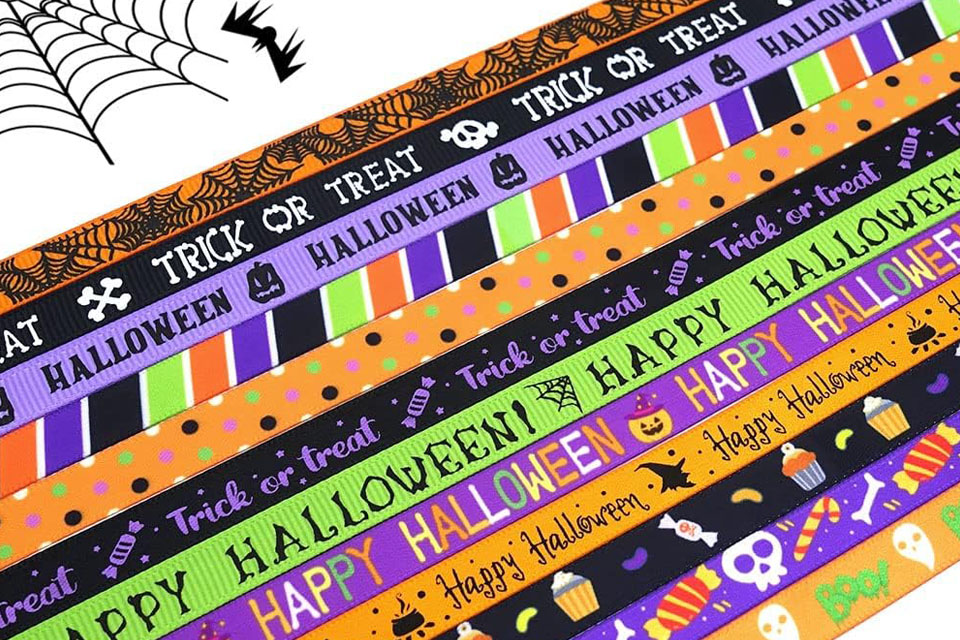

Ribbons are more than just decorative elements; they are versatile tools that add elegance, charm, and a personal touch to a myriad of products and packaging.

Solid Deco Mesh: Tech-Driven Versatility in Décor Solutions

Solid deco mesh, also known as decorative mesh, is a versatile, flexible material that has revolutionized the world of crafting, event planning, and interior design.

(Eco-Friendly Satin Ribbons): Sustainable and Recyclable Solutions for Every Occasion

In today’s environmentally conscious world, choosing sustainable and eco-friendly materials is more important than ever.