Today we will be exploring the fascinating world of ribbon manufacturing, where artistry meets industrial precision. Whether you’re a craft enthusiast, event planner, or business owner, understanding the ribbon production process can help you make better purchasing decisions and appreciate the craftsmanship behind these versatile decorative elements.

What Makes Professional Ribbon Manufacturing Different from DIY Production?

Professional ribbon manufacturing involves sophisticated machinery and precise quality control that sets it apart from handmade alternatives. Modern ribbon factories employ advanced weaving technologies that can produce thousands of meters of consistent, high-quality ribbon daily. The key differences include:

- Automated tension control systems

- Computer-controlled pattern generation

- Industrial-grade fiber processing

- Rigorous quality testing protocols

How Are Different Types of Ribbon Materials Selected and Processed?

The selection of materials is crucial in determining the final quality of the ribbon. Manufacturers carefully choose between:

- Satin Ribbons: Made from polyester or silk with a glossy finish

- Grosgrain Ribbons: Featuring distinctive ribbed texture

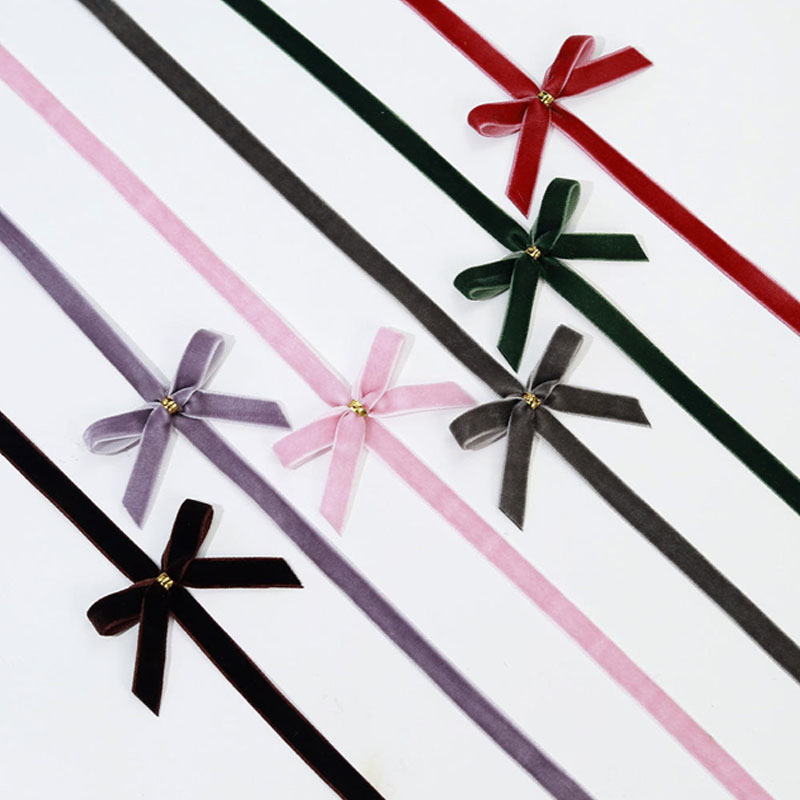

- Velvet Ribbons: Created with plush, soft fibers

What Role Does Technology Play in Modern Ribbon Production?

Today’s ribbon manufacturing relies heavily on advanced technology to ensure precision and efficiency. Key technological components include:

- Computerized weaving machines

- Automated cutting systems

- Digital printing equipment

- Quality control sensors

How Does Quality Control Work in Ribbon Manufacturing?

Quality assurance is paramount in ribbon production. Every stage of manufacturing undergoes strict testing:

- Raw material inspection

- Weave pattern verification

- Color consistency checks

- Edge finishing assessment

- Strength and durability testing

What Are the Environmental Considerations in Ribbon Production?

Modern manufacturers are increasingly focused on sustainability:

- Use of recycled materials

- Water conservation in dyeing processes

- Energy-efficient machinery

- Waste reduction programs

- Eco-friendly packaging solutions

How Do Seasonal Demands Impact Ribbon Manufacturing?

The ribbon industry experiences significant seasonal variations:

- Holiday rush periods (Christmas, Valentine’s Day)

- Wedding season demands

- Back-to-school timing

- Festival-specific productions

What Custom Options Are Available in Ribbon Manufacturing?

Customization capabilities include:

- Custom printed logo designs

- Special width specifications

- Unique color combinations

- Specialty finishes

- Custom packaging options

How Does Pricing Work in the Ribbon Industry?

Pricing factors in ribbon manufacturing include:

- Raw material costs

- Production volume

- Customization requirements

- Seasonal demand

- Market competition

What Are the Latest Trends in Ribbon Manufacturing?

Current industry trends include:

- Sustainable materials

- Digital printing advancements

- Smart packaging solutions

- Metallic and specialty finishes

- Multi-functional ribbons

What Are the Future Prospects for Ribbon Manufacturing?

The future of ribbon manufacturing looks promising with:

- Increased automation

- Sustainable innovations

- Enhanced customization capabilities

- Global market expansion

- Digital integration

Frequently Asked Questions

What is the minimum order quantity for custom ribbons? Minimum order quantities vary by manufacturer and product type, typically ranging from 100 to 1000 yards for custom orders.

How long does it take to manufacture custom ribbons? Production time usually ranges from 7-14 days, depending on complexity and quantity.

Can ribbons be made with eco-friendly materials? Yes, many manufacturers now offer sustainable options made from recycled polyester or organic cotton.

What affects the durability of manufactured ribbons? Factors include material quality, weaving technique, dye stability, and edge finishing methods.

Are there different grades of ribbon quality? Yes, ribbons are typically categorized into different grades based on material quality, weaving density, and finishing techniques.

Key Takeaways:

- Professional ribbon manufacturing combines traditional craftsmanship with modern technology

- Quality control is essential at every stage of production

- Customization options are extensive and continually expanding

- Sustainability is becoming increasingly important in the industry

- Market demands vary significantly by season and application

For more information about specific ribbon types and applications, visit our detailed guides on special occasion ribbons and wired ribbons.