As a leading ribbon manufacturer, we’ll share professional techniques to keep your ribbons looking crisp and polished. This comprehensive guide covers everything from simple at-home solutions to professional-grade methods used in our ribbon factory.

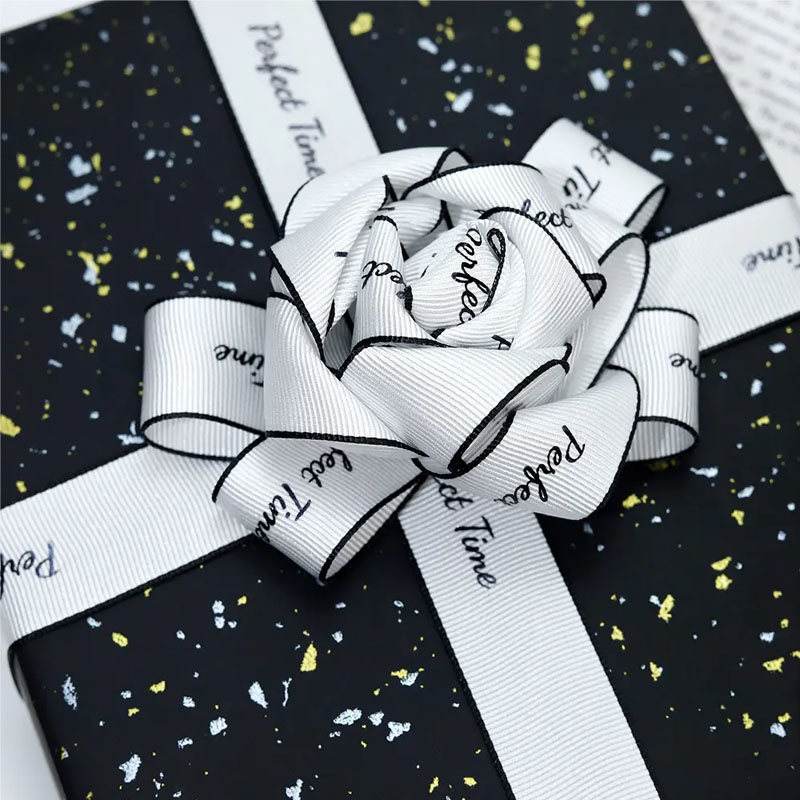

Professional-grade ribbon bows with sealed edges for lasting beauty

Why Do Ribbons Fray and Why Should You Care?

Ribbon fraying occurs when the woven fibers at the cut edges begin to unravel. Different types of ribbons have varying tendencies to fray:

What Are the Best Tools for Cutting Ribbon?

Using the right tools is crucial for preventing fraying:

- Sharp fabric scissors (recommended)

- Rotary cutters with self-healing mats

- Professional ribbon cutting machines

- Hot knife cutters for synthetic ribbons

How Can You Use Heat Sealing Techniques?

Heat sealing is highly effective for synthetic ribbons:

- Using a lighter:

- Hold ribbon end near (not in) flame

- Move quickly across edge

- Watch for slight melting

- Wood burning tool method:

- Set to low temperature

- Gently seal edges

- Work in ventilated area

Safety Warning: Always exercise caution with heat tools and work in a well-ventilated space.

What Chemical Solutions Prevent Fraying?

Several products can help seal ribbon edges:

ProductBest ForApplication TimeDurabilityFray CheckAll ribbons15-20 minutesHighClear nail polishThin ribbons10 minutesMediumFabric sealantThick ribbons30 minutesVery high

How Do Professional Ribbon Manufacturers Prevent Fraying?

In our manufacturing process, we use:

What Are Quick DIY Solutions for Ribbon Fraying?

Simple at-home techniques include:

- Cutting at a diagonal angle

- Using clear craft glue

- Applying anti-fraying spray

- Creating folded ends

Frequently Asked Questions

How long should I wait for edge sealants to dry?

Most sealants require 15-30 minutes to dry completely. For best results, allow 24 hours before handling extensively.

Can all ribbon types be heat-sealed?

No, only synthetic ribbons like polyester and nylon respond well to heat sealing. Natural fibers require different treatment methods.

What’s the best method for delicate ribbons?

For delicate ribbons, use fabric sealant or fray check products rather than heat-based methods.

How can I prevent fraying while working with ribbons?

Handle ribbons gently and use sharp scissors for all cuts. Consider pre-treating edges before starting your project.

Key Takeaways:

• Choose the right cutting tools

• Select appropriate sealing methods for each ribbon type

• Follow safety precautions with heat-based techniques

• Consider professional-grade products for best results

• Test methods on scrap pieces first

• Store ribbons properly to prevent damage

Remember to visit our ribbon factory for professional-grade ribbons and expert advice on ribbon care and handling.