Whether you’re a retail & craft consumer, event planner, florist, or part of a fashion & apparel brand, knowing how to prevent your ribbons from fraying is essential for maintaining a professional and polished look. In this comprehensive guide, we’ll explore the most effective methods to stop ribbon fraying, ensuring your projects remain flawless and long-lasting.

What Causes Ribbon to Fray?

Fraying occurs when the fibers of the ribbon start to unravel, leading to a messy and unattractive appearance. Several factors contribute to ribbon fraying:

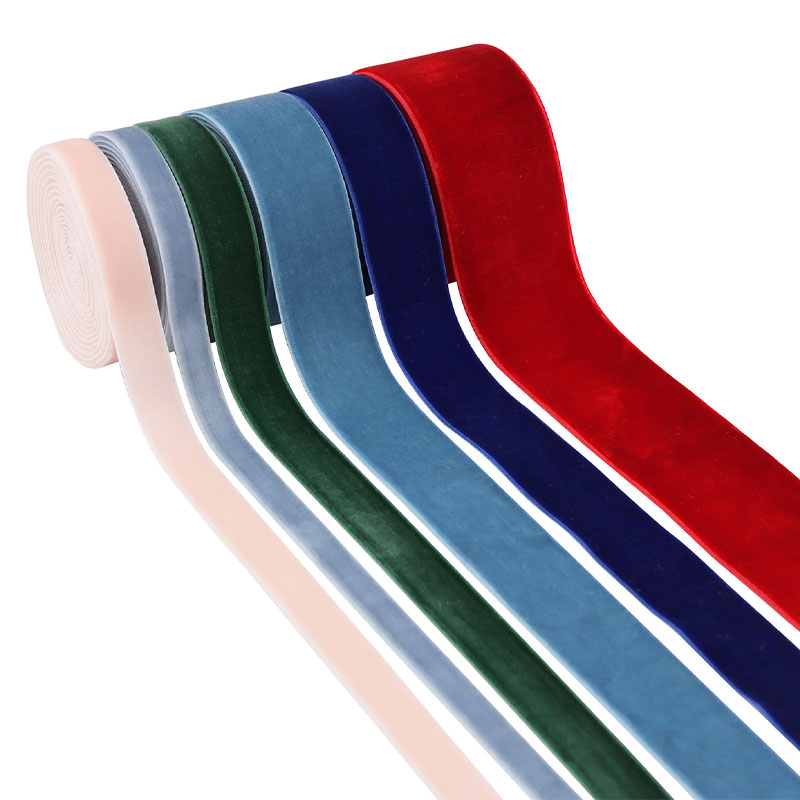

- Material Quality: Lower quality ribbons are more prone to fraying due to weaker fibers.

- Cutting Techniques: Using dull or inappropriate scissors can cause the edges to fray.

- Handling and Storage: Excessive handling or improper storage can weaken the ribbon fibers over time.

- Exposure to Elements: Moisture, heat, and sunlight can degrade the ribbon material, increasing the likelihood of fraying.

Understanding these causes helps in selecting the right ribbon and handling it with care to minimize fraying.

How Does Heat Sealing Prevent Fraying?

Heat sealing is a popular method to stop ribbon fraying by melting the edges slightly to fuse the fibers together. Here’s how it works:

- Application of Heat: Using a tool like a lighter or a heat sealer, apply a controlled amount of heat to the ribbon’s edge.

- Melting the Fibers: The heat melts the fibers just enough to bond them without damaging the ribbon.

- Cooling and Setting: Allow the ribbon to cool, which solidifies the fused fibers, preventing them from unraveling.

Advantages of Heat Sealing:

- Durability: Provides a long-lasting solution to fraying.

- Simplicity: Easy to perform with basic tools.

- Versatility: Suitable for various ribbon types, including satin and grosgrain.

Safety Tip: Always use caution when applying heat to prevent burns or accidental damage to the ribbon.

What Are the Best Ways to Stop Ribbon Fraying?

There are several effective methods to prevent ribbon fraying, each with its own set of advantages:

1. Heat Sealing

- Tools Needed: Lighter, heat sealer, or wood burning tool.

- Process: Apply heat to the ribbon ends to melt and fuse the fibers.

- Best For: Satin ribbon, grosgrain ribbon.

2. Clear Nail Polish

- Tools Needed: Clear nail polish, brush.

- Process: Paint the ribbon ends with clear nail polish to seal the fibers.

- Best For: Delicate ribbons where heat might cause damage.

3. Fray Check

- Tools Needed: Fabric glue or fray stop liquid.

- Process: Apply a thin layer of fray stop to the ribbon ends.

- Best For: Quick fixes and various ribbon types.

4. Binding with Thread

- Tools Needed: Needle, thread.

- Process: Stitch the ribbon ends to secure the fibers.

- Best For: Handmade projects requiring added strength.

5. Using a Wood Burning Tool

- Tools Needed: Wood burning tool.

- Process: Gently burn the ribbon ends to fuse the fibers.

- Best For: Thick ribbons like grosgrain.

Comparison Table:

| Method | Durability | Ease of Use | Suitable Ribbons |

|---|

| Heat Sealing | High | Moderate | Satin, grosgrain |

| Clear Nail Polish | Medium | Easy | Delicate, fine ribbons |

| Fray Check | Low-Medium | Easy | All types |

| Binding with Thread | Medium | Moderate | Handmade, decorative |

| Wood Burning Tool | High | Advanced | Thick ribbons |

Can Clear Nail Polish Be Used to Stop Ribbon from Fraying?

Yes, clear nail polish is an effective and simple method to prevent ribbon fraying, especially for delicate and fine ribbons. Here’s how to do it:

- Prepare the Ribbon: Cut the ribbon ends cleanly with sharp scissors to minimize fraying.

- Apply Nail Polish: Using a small brush, apply a thin layer of clear nail polish to the cut ends of the ribbon.

- Let It Dry: Allow the nail polish to dry completely. This forms a protective barrier that seals the fibers.

Pros:

- Ease of Use: Requires minimal tools and time.

- Flexibility: Suitable for various ribbon types and sizes.

Cons:

- Durability: May wear off over time with frequent handling.

- Appearance: Excessive application can make the ends stiff or sticky.

Expert Tip: Apply multiple thin layers rather than one thick layer to ensure even coverage and better flexibility.

How to Use a Lighter to Seal Ribbon Ends

Using a lighter is a quick and effective way to stop ribbon fraying by melting the ends to fuse the fibers. Follow these steps for best results:

Step 1: Prepare the Ribbon

- Cut Cleanly: Use sharp scissors to trim the ribbon ends neatly.

- Safety First: Work in a well-ventilated area away from flammable materials.

Step 2: Apply Heat

- Control the Flame: Hold the lighter flame about 1-2 inches above the ribbon end.

- Move Quickly: Pass the ribbon end through the flame quickly to prevent scorching.

- Melt Slightly: Aim to just melt the fibers enough to seal them without creating a rigid edge.

Step 3: Cool and Shape

- Allow to Cool: Let the ribbon cool naturally; it will solidify quickly.

- Shape as Needed: Gently shape the ribbon to retain its natural curve and flexibility.

Safety Precautions:

- Avoid Burns: Handle the lighter carefully to prevent accidental burns.

- Minimal Flame Exposure: Excessive heat can damage the ribbon’s color and texture.

Pro Tip: Practice on a scrap piece of ribbon first to get the hang of the technique without risking your project.

Is Using a Wood Burning Tool Effective for Preventing Fraying?

Yes, a wood burning tool can be an effective method to prevent ribbon fraying, especially for thicker ribbons like grosgrain. Here’s how to use it:

Step 1: Prepare the Ribbon

- Cut Neatly: Trim the ribbon ends with sharp scissors to reduce fraying.

- Secure the Ribbon: Hold the ribbon taut to ensure even application of heat.

Step 2: Apply Heat with the Tool

- Set the Temperature: Adjust the wood burning tool to a low to medium setting.

- Burn the Ends: Gently press the tool against the ribbon ends, moving it steadily to fuse the fibers.

- Avoid Overheating: Too much heat can discolor or overly stiffen the ribbon.

Step 3: Cool and Inspect

- Let It Cool: Allow the ribbon to cool before handling.

- Check Sealing: Ensure the fibers are fused together without any loose ends.

Advantages:

- Precision: Allows for controlled application of heat.

- Durability: Creates a strong seal that withstands handling.

Disadvantages:

- Skill Required: Requires practice to avoid damaging the ribbon.

- Equipment Needed: Requires a wood burning tool, which may not be readily available.

Expert Insight: “Using a wood burning tool provides a clean and professional finish, perfect for high-quality ribbon projects,” says a professional decorator.

What Are the Pros and Cons of Different Fray-Stopping Methods?

Choosing the right method to stop ribbon fraying depends on your project’s needs and the type of ribbon you’re using. Here’s a comparison of various methods:

Heat Sealing

Pros:

- Long-lasting

- Quick and efficient

Cons:

- Requires careful handling

- May not be suitable for all ribbon types

Clear Nail Polish

Pros:

- Easy and accessible

- Minimal tools required

Cons:

- Less durable

- Potential for stiffness

Fray Check

Pros:

- Simple application

- Suitable for various ribbons

Cons:

- Can be visible if over-applied

- May require reapplication over time

Binding with Thread

Pros:

- Adds strength

- Customizable

Cons:

- Time-consuming

- Requires sewing skills

Wood Burning Tool

Pros:

- Precise and durable

- Professional finish

Cons:

- Requires specific tools

- Higher skill level needed

Decision Table:

| Method | Durability | Ease of Use | Suitable Ribbons |

|---|

| Heat Sealing | High | Moderate | Satin, grosgrain |

| Clear Nail Polish | Medium | Easy | Delicate, fine ribbons |

| Fray Check | Low-Medium | Easy | All types |

| Binding with Thread | Medium | Moderate | Handmade, decorative |

| Wood Burning Tool | High | Advanced | Thick ribbons |

Choosing the Right Method: Consider the ribbon type, project requirements, and available tools when selecting a fray-stopping technique.

How to Maintain Ribbon Quality Over Time

Maintaining ribbon quality ensures your projects remain beautiful and fray-free. Follow these tips to preserve your ribbons:

1. Proper Storage

- Avoid Moisture: Store ribbons in a dry environment to prevent mold and weakening of fibers.

- Keep Away from Sunlight: Prolonged exposure to sunlight can fade colors and degrade materials.

- Use Protective Containers: Store ribbons in airtight containers or garment bags to protect them from dust and pests.

2. Gentle Handling

- Avoid Excessive Stretching: Handle ribbons with care to prevent stretching and fiber damage.

- Use Clean Hands: Oils and dirt from hands can weaken ribbon fibers over time.

3. Regular Inspection

- Check for Wear and Tear: Regularly inspect ribbons for signs of fraying or damage.

- Address Issues Promptly: Fix any frayed ends immediately to prevent further deterioration.

4. Proper Cutting Techniques

- Use Sharp Scissors: Ensure clean cuts to minimize fraying.

- Cut at an Angle: Cutting ribbons at a 45-degree angle can help reduce fraying.

Pro Tip: Rolling ribbons loosely instead of folding them can help maintain their shape and prevent creasing.

Creative Ways to Finish Ribbon Ends

Finishing ribbon ends creatively can add a unique touch to your projects. Here are some innovative ideas:

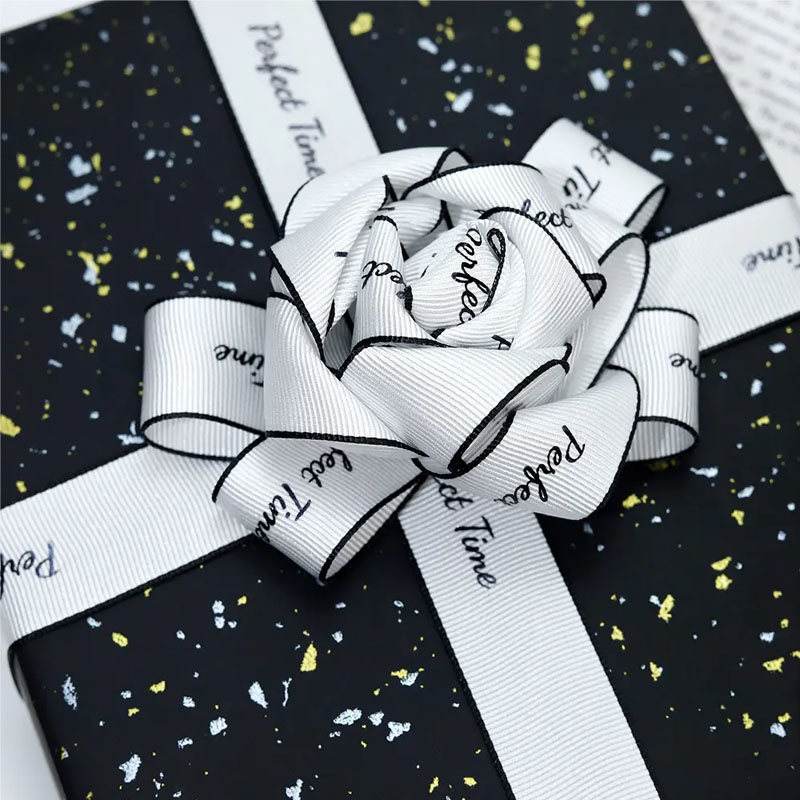

1. Twisted Bows

- Technique: Twist the ribbon ends into small bows and secure with a knot or glue.

- Application: Perfect for gift wrapping, hair accessories, and decorative bows.

2. Fringe Edges

- Technique: Create a fringe by making multiple small cuts along the ribbon edge.

- Application: Ideal for adding texture to decorations, clothing, and craft projects.

3. Beaded Ends

- Technique: Thread beads onto the ribbon ends and secure with a knot or glue.

- Application: Adds sparkle and elegance to ribbon projects, suitable for fashion and gift packaging.

4. Layered Ribbons

- Technique: Layer different widths or colors of ribbon and secure the ends together.

- Application: Creates a multi-dimensional effect, ideal for bouquets and decorative arrangements.

5. Sewn Embellishments

- Technique: Sew small embellishments like sequins, buttons, or charms onto the ribbon ends.

- Application: Enhances the visual appeal, perfect for handmade crafts and fashion accessories.

FAQs

How long does it take to stop ribbon from fraying?

Stopping ribbon fraying is a quick process that typically takes less than five minutes per ribbon end, depending on the method used.

Can I use any type of glue to prevent ribbon fraying?

Yes, you can use clear craft glue, fray stop liquid, or specialized fray-prevention adhesives to stop ribbon fraying effectively.

Is heat sealing safe for all ribbon types?

Heat sealing is generally safe for synthetic ribbons like satin and grosgrain. However, it may not be suitable for natural fibers or ribbons with delicate embellishments.

What is the best method to stop ribbon fraying for delicate projects?

For delicate projects, using clear nail polish or fray stop liquid is recommended as it provides a gentle and effective seal without adding stiffness.

Can ribbon fraying be completely prevented?

While it’s challenging to eliminate fraying entirely, using the right techniques and proper ribbon care can significantly reduce and manage fraying.

Summary

- Understand Causes: Recognize factors leading to ribbon fraying, such as material quality and handling.

- Effective Methods: Utilize heat sealing, clear nail polish, fray check, threading, or wood burning tools to stop fraying.

- Choose Wisely: Select the best method based on ribbon type and project needs.

- Maintain Quality: Store ribbons properly and handle them gently to prolong their lifespan.

- Creative Finishes: Enhance your projects with twisted bows, fringes, beads, layered ribbons, or sewn embellishments.

- FAQs: Address common questions to ensure effective fray prevention.

By implementing these strategies, you can keep your ribbons looking pristine and professional, enhancing the overall quality of your crafts and decorations. For high-quality ribbons and more crafting tips, visit RibbonOEM and explore our extensive collection designed to meet all your ribbon needs.